How does Felder’s new Preventive Contact System work? Is it better than SawStop?

Ever since Steve Gass of SawStop invented his finger-detection technology, Sawstop has been the only major manufacturer* to sell table saws that detect contact with the user and automatically stop the blade.

Last year, Felder announced their innovative Preventive Contact System, which promises some great benefits: the saw blade retracts before contact, the blade can be reused, and there is no cartridge to be replaced.

Felder starts selling their first machines with this new tech in the following weeks and months, so I thought it was a good time to take a closer look.

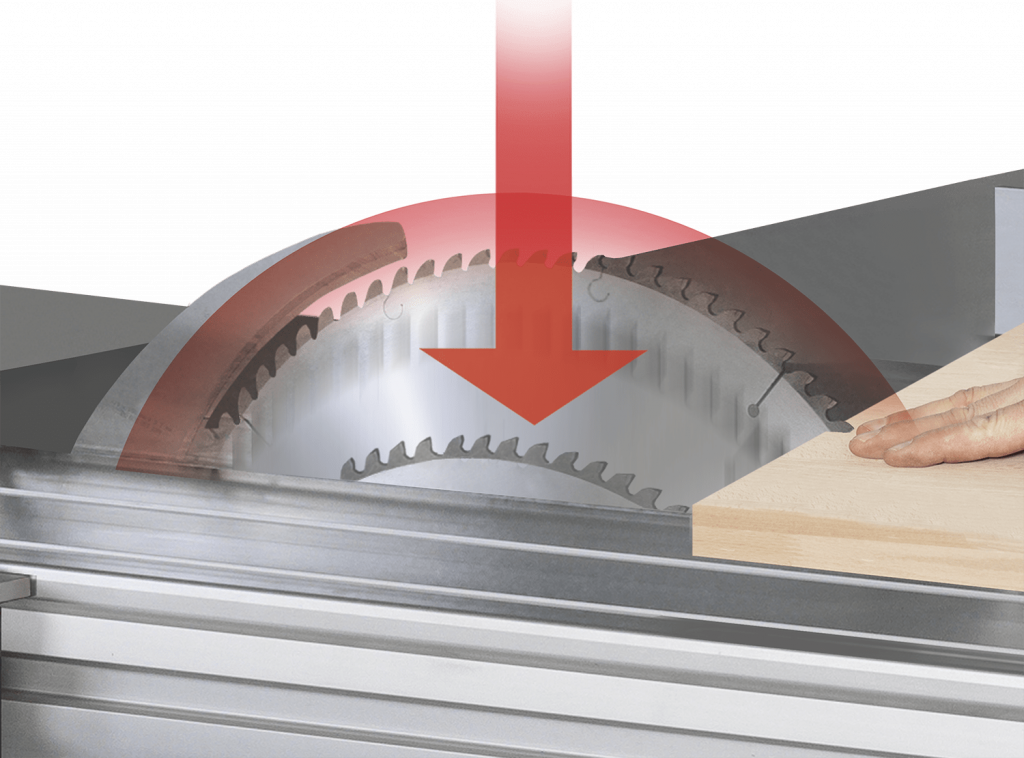

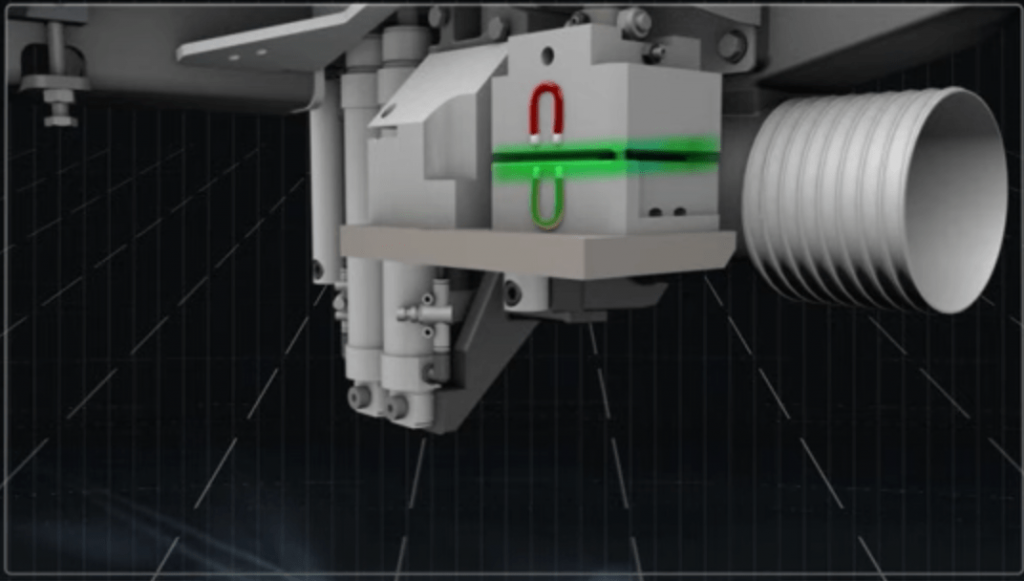

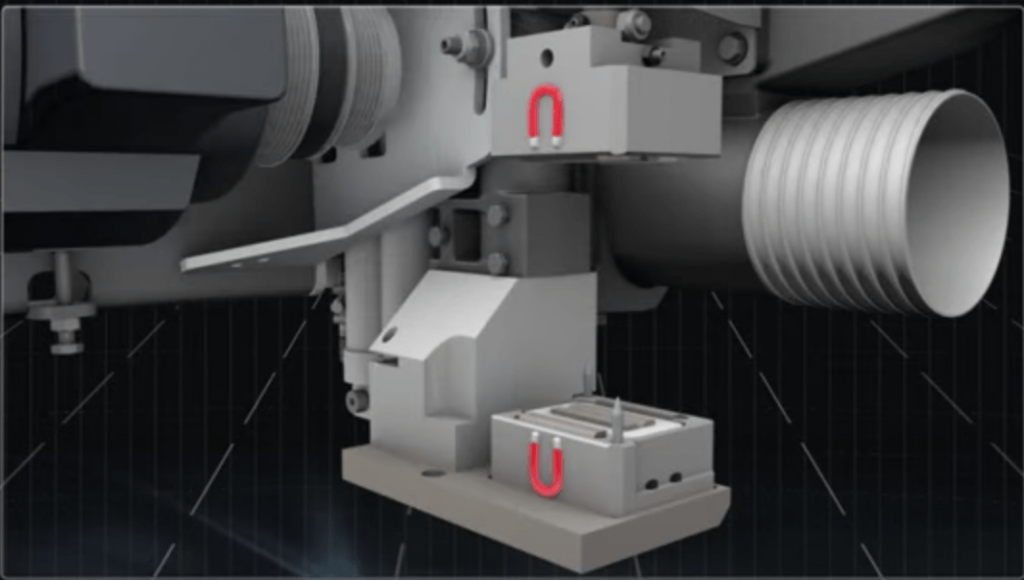

Felder’s system consists of two main parts, namely the detection of the user’s hand, and the mechanism for pulling the saw blade down. The motion is detected by an electromagnetic field around the blade, and the pulling down is done by a clever system of magnets that reverse in polarity.

By generating an electromagnetic field around the saw blade, PCS can detect incoming movement before it actually comes into contact with the blade. This supposedly works both for fast and slow movement, and fires within milliseconds.

The entire saw aggregate is held together by two strong electro-magnets. The polarity of these magnets holds them together, but when incoming user contact is detected, the polarity is reversed, forcing the two magnets apart extremely rapidly.

This brings the entire saw unit down very quickly, which means there is no need to put a brake on the saw blade. Another advantage is that there is no cartridge needed. With a push of a button on the control screen, the magnets connect back together again and you can return to work within a minute. The safety system also automatically restarts again, so your next cut will be just as safe.

Felder also released this longer video (see below), that explains the whole technical system in a bit more detail.

Let me first say that I am obviously not a patent expert (the inventor of SawStop was in fact a patent lawyer). However, it is still possible to say something about the differences between SawStop and Felder, and why Felder has succeeded in bringing out a new system while competitors like Bosch have had to pull their system from the market because of patent infringement lawsuits.

What both systems have in common is that they use an electric current to detect user contact. However, while SawStop’s system runs a current through the sawblade, Felder’s PCS creates an electric field around the blade, which detects contact before it actually hits the blade.

The rest of the system is entirely different. In SawStop’s patent applications, you can see that their braking system is a key part of their patent. Felder has cleverly circumvented this by not including a brake at all. With the magnetic switch, they pull down the entire saw aggregate instead.

This is probably the key reason why Felder’s system doesn’t infringe on SawStop patent. The fact that it also gets rid of the cartridge, and keeps the sawblade intact, makes it even better.

This table summarizes the differences between the two systems.

| Felder PCS | SawStop |

| No Cartridge | Cartridge |

| Blade can be reused | Blade Destroyed |

| Triggered before contact | Triggered on contact |

| Lowest priced saw: ~15000 | Lowest priced saw: ~1500 |

| Works with any sawblade | Sawblades need to be specific size and material |

| New to the market | Commercially proven |

Other Systems: Some other companies are working on similar technology, such as Griggio, which has had the Unica Safe system since 2015, but that is limited to panel saws and triggers on contact. Alterndorf is working on a system with camera tracking, but that seems to be much more difficult to make 100% secure.

Given all the advantages Felder’s new system has, it is easy to think they will dominate the market and give SawStop a really hard time. Felder’s system is simply better in all aspects. However, there’s a few bumps in the road for Felder.

Firstly, it’s still an unproven system. It is currently only available on one very expensive sliding table saw, which hasn’t even been delivered yet. This means it will take time for Felder’s system to prove itself.

Public trust and faith in this kind of system are probably the best selling points. It takes time to build up a reputation, something which SawStop has been doing for many years.

Felder’s employees test the system with their own fingers on trade shows, as can be seen in the video below. At least that shows that they are very confident in their own product.

Currently, the Preventive Contact System is only offered on the Format 4 Kappa 550 sliding table panel saw. It is one of the most expensive machines the Felder group makes.

There are plans to eventually bring this technology to cheaper saws, even the Hammer range. However, R&D is still working on bringing the cost down and it could take years before we can see it in Hammer machines.

And even Hammer machines are quite expensive. SawStop manages to offer their system in saws as cheap as $1500. Until Felder is able to do that (perhaps through licensing), SawStop will keep a firm grip on the lower to medium end of the market.

(*) There have been some alternatives, like Bosch’s REAXX system, but these have been taken off the market because of potential infringement of SawStop’s patents.

© Machine Atlas 2026

Nice writeup, Rob, thanks for the info. Just one small suggestion: a “break” is an interruption, a “brake” is the word for a machine part that stops something.

Hi Dave, thanks for your feedback. I’ve updated the article with the correct usage of ‘brake’!

Rob

How much does the machine cost with the PCS?