Made in the USA, lightweight, powerful, and great clamping force, what’s not to like about these clamps?

In this review, I’ll share my experiences with Dubuque’s bar clamps, and how I used them in a recent project.

I was working on a small cabinet, and halfway the build process I realized I didn’t have the right clamps for the project – 1400mm + clamps for gluing the vertical side of the cabinet were what I needed to buy.

During my search for the right clamps I found that the best clamps were too expensive for me (Bessey’s KRE line), and the cheapest were simply of poor quality. I ended up with a choice between pipe clamps and Dubuque’s aluminium lightweight bar clamps (also called sash clamps or sash cramps in the UK).

I ended up buying the Dubuque bar clamps, and couldn’t be more satisfied. Keep reading to find out why.

The advantage of pipe clamps is that you can resize them just by buying a shorter or longer pipe, and they’re extremely stable and powerful. However, they’re also very heavy and not convenient to use. I rarely use the two pipe clamps I have because they’re so heavy that I avoid them unless absolutely necessary.

Dubuque’s clamps on the other and are extremely light for their size. Even the 1500 mm (60″) version I bought is easy to handle, and as such can also be conveniently used on smaller projects.

Dubuque clamps can clamp up to 4500 Newton, which is more than enough for most jobs. In comparison, premium Bessey body clamps have a force of up to 8000 Newton, but in my experience that is overkill. If you find yourself needing that amount of force to hold a tight joint, your joint isn’t built right in the first place.

If you’re joining properly built joints that align well, probably 2000 Newton is the most you’ll really need. I love my (cheap) Bessey Uniklamps and they only provide a force of up to 1500 Newton and I’ve rarely found them underpowered for most projects (please share your experience if you think otherwise).

Although Dubuque clamps aren’t the very cheapest, they’re actually extremely good value for money. Cheaper clamps have strong limitations, and in my case pipe clamps add up to approximately the same cost. If you have some old pipes lying around, pipe clamps are obviously cheaper however.

Aluminium bar clamps have a bad reputation due to the cheapest versions which are made of very lightweight and thin extrusions to keep costs down. Dubuque instead uses much thicker extrusions which prevents bowing (see image). The only alternative I know of with similarly strong extrusions are the JUUMA clamps sold by Fine Tools, but those are more expensive.

Another advantage of aluminium is that it doesn’t stain. While metal pipes can stain certain woods when they come into contact with glue, this is not a risk with aluminium.

Quality control is often a serious problem with more affordable products made in Asia. The overall product may be decent, but there are large variations in quality between individual items. Dubuque clamps are made in Iowa, USA and have had the same design for years. They’re very reliable, and between the three clamps I bought I noticed no variations and all of them were of excellent build quality.

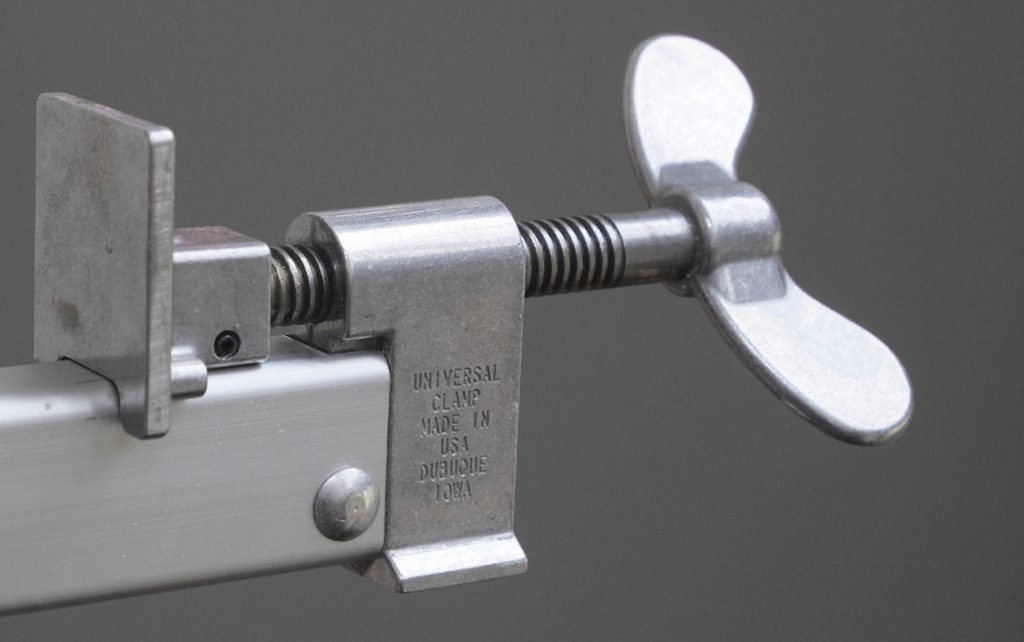

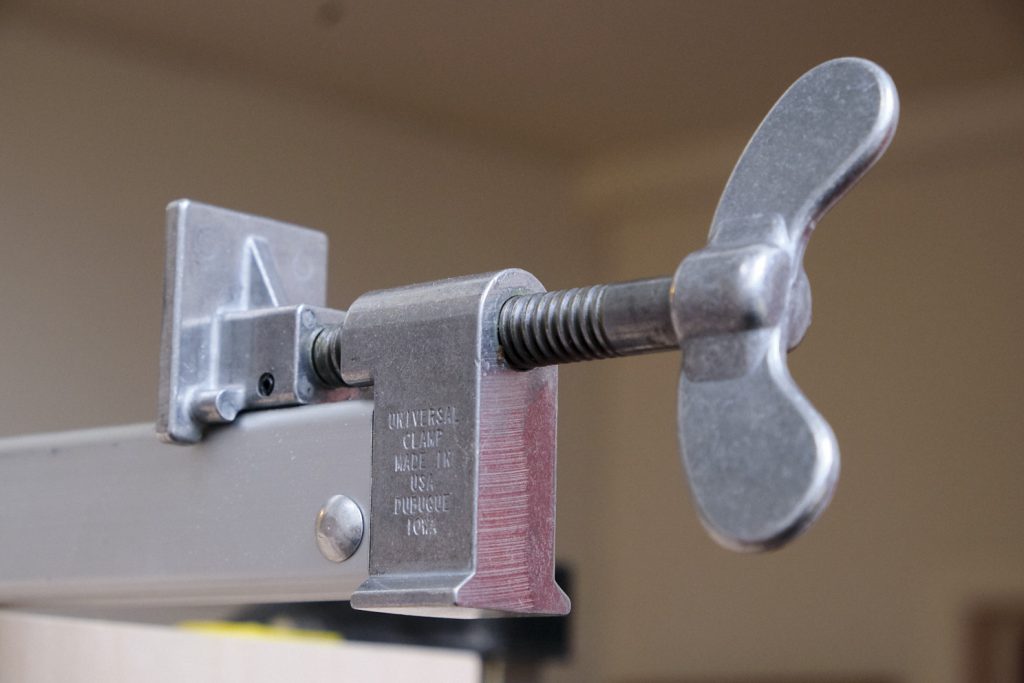

One small downside is that the tightening mechanism is quite long and makes a long clamp even longer. Also the butterfly handle isn’t the smallest, so if you were to position two clamps very closely, the ends of the handle might bump into the other clamp making it hard to twist it. But with clamps this size that is not often the case, as they’re usually quite spaced out.

In comparison, the JUUMA clamps seem to have found a more elegant solution, but I didn’t find that worth the premium price. Paul Sellers has done a review of those clamps and compares them with the Dubuque ones and finds them equally good.

All in all, I’m very satisfied with the Dubuque bar clamps. They’re much easier to handle than heavy pipe clamps while providing sufficient clamping pressure. The build quality is excellent and they’re not too expensive, making them great all-round clamps.

Unless you have a specialist job requiring extreme clamping pressure, or money doesn’t play a role and you can go for the most expensive Bessey clamps, I can see no reason not to recommend these Dubuque bar clamps.

© Machine Atlas 2025

There are no comments yet, be the first to leave one!

Every comment on MachineAtlas is read and answered. And if you know some useful info or tips, please share them. You could really help out some fellow woodworkers!