Is the Festool Domino an essential tool for every woodworker? Find out in my in-depth review.

The Festool Domino is one of the most innovative woodworking tools introduced in the last 20 years. But how useful is it really? Is it an essential tool in any workshop? I’ve been using it for a year now and have written down my thoughts in this review.

The Festool Domino does one thing: it creates mortises. These mortises can then be fitted with floating tenons that resemble domino stones, hence the name Festool Domino.

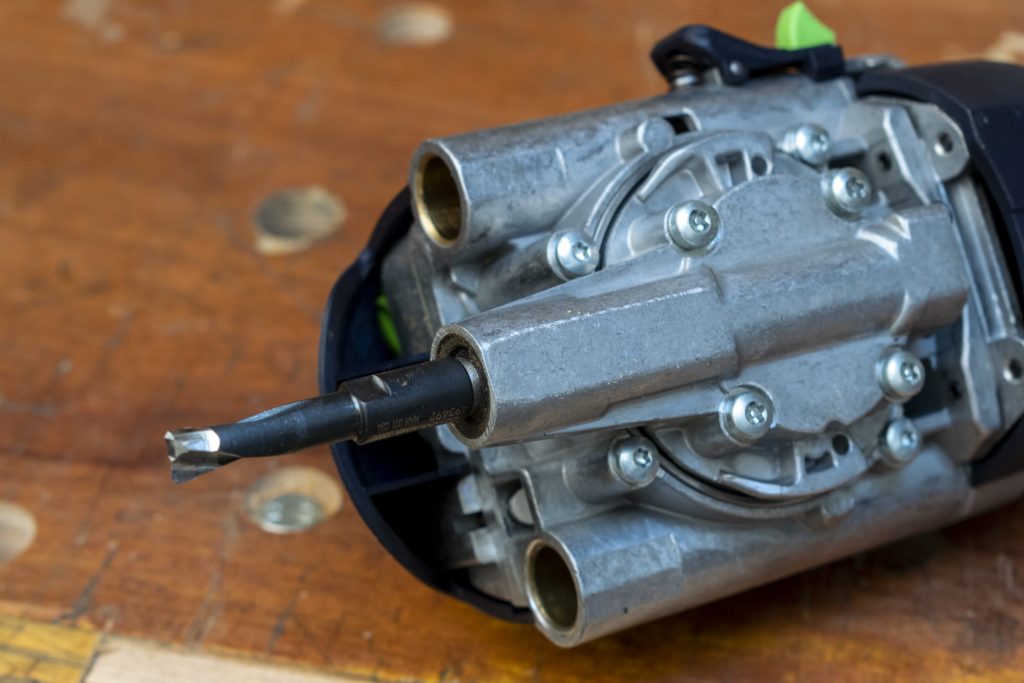

What makes the Domino unique is that these mortises can be made extremely quickly, and with perfect alignment. It uses a special bit that rotates, similar to a regular drill. But it also moves from left to right at an angle really quickly. You just push the rotating bit into the wood and it automatically creates a perfectly clean mortise in under 2 seconds.

By changing to a different size bit you can make smaller or larger mortise holes. Festool supplies dominos for each size, both for indoor (Beech), and outdoor use (Sipo Mahogany). One downside is that these dominos are not very cheap. If you want to, you can make your own dominos on the router table as well, but personally I find it too much work.

Besides regular wooden dominos that are glued in, Festool also offers a range of connectors that can be assembled and disassembled. This is great if you want to create flat-pack (like Ikea) furniture. I haven’t used these special connectors myself yet.

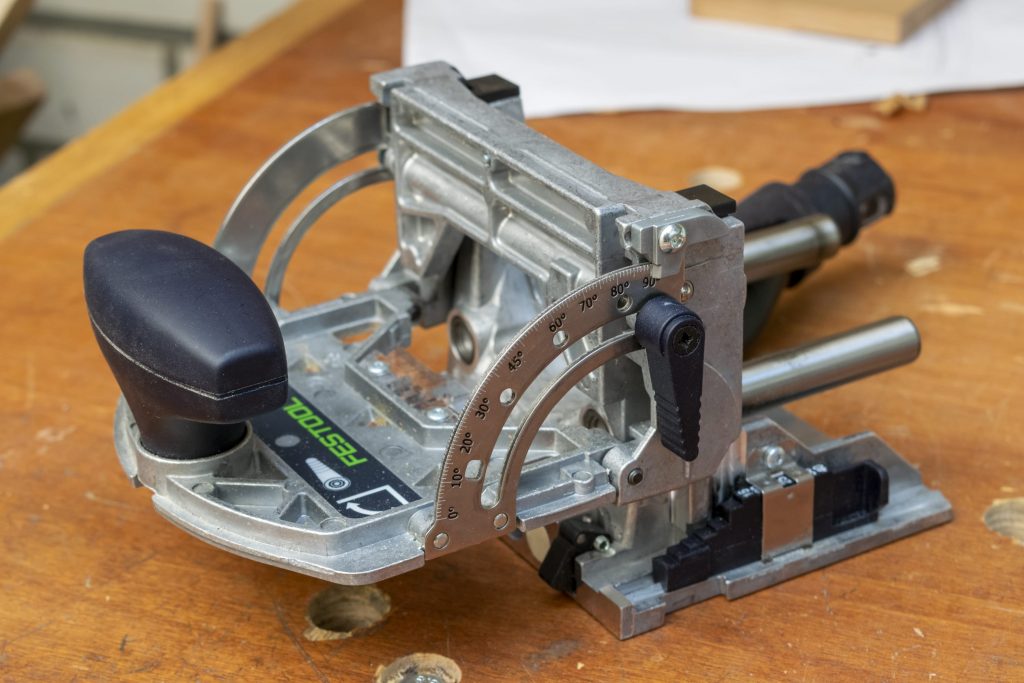

There are five variables you can change on the Domino DF 500 to make the specific connection you want.

The choice of the bit size depends on the size of your workpieces. Usually you want your tenon to be no thicker than a third of the thickness of the stock. But if you have really thick stock, you might want to use two tenons.

The vertical location is relatively straightforward. You want to position your tenon (if it’s just one) in the middle. On the side there is a slider with some preset thicknesses that help you find the center on standard plywood sizes really quickly.

The depth of the mortise can be set on the back with a spring-loaded button. It has several depth settings, from 12 to 28 mm. On two equally thick pieces, you probably want both mortises the same depth. But sometimes one piece is much thinner than the other, so you want some extra depth on one side, and less on the other.

You can adjust the angle of the mortise with the fence. It can be set continuously from 0 to 90 degrees, but also has some positive stops where it kind of ‘clicks’, so you can quickly set it on for example 45 degrees for creating a perfect miter joint.

Lastly, the width of the mortise can be set to three sizes: Equal to the width of a tenon, slightly wide, and even wider. Usually you make a few mortises on the narrowest setting, to make sure the alignment is perfect, and then the rest on the slightly wider setting to allow for a little bit of play to make up for any inaccuracies.

To make sure your mortises line up perfectly, you simply put the two pieces in the right position and draw a line on both where you want the mortise to be. You then align that line with the center mark on the Domino and you are guaranteed perfect alignment. There is also a center mark on the bottom of the machine, so you can lign it up from both sides.

If you want to join wider boards, for example for a table top, you need multiple mortises in a row. You can use the same principle there, or you can reference each mortise from the last one. There are two black pins on the Domino that you can put in the previously created mortise hole to make sure the distance between them is always the same. I personally find simply drawing lines to be a little easier and more accurate.

Because the domino creates mortises so quickly, it means it removes wood really fast, and all those wood chips need to go somewhere. Good dust extraction therefore is essential on the domino. The dust port is 27mm wide. I got lucky, because my Makita shop vacuum had an adapter that fit perfectly. Otherwise you may need to get one of Festool’s adapters. Thanks to the excellent dust extraction, there is almost zero dust when using the Domino.

The machine is quite noisy, so hearing protection is recommended.

Like with most Festool products, the build quality of the Domino is excellent. It is heavy, the fences are made of durable metal and the body is protected by hard plastic.

The machine consists of two main parts that can be separated (which you’ll have to do when you want to change the bit). The body with the bit, and the front part with the fence. The front has two metal rods on it that slide in holes on the body.

There are only two ‘weak’ parts that I could find. Firstly the small black alignment pins. I can definitely see them breaking off, wearing out, or the springs behind them becoming fatigued after heavy use. Festool seems to think the same, because they supply replacement pins standard in the box.

Interesting: Those black alignment pins actually used to be round on earlier versions of the Domino. Some users say those worked better, but it violated a patent by Mafell so Festool had to change them

The other vulnerable part is the dust extraction port. It is made from a less strong plastic, and if you would make a wrong move, I think it could snap off. But if you don’t do anything stupid it should be fine, so it’s not a major issue.

Also, if something would go wrong, there is still Festool’s 3-year warranty and repair program.

The Festool Domino is a unique machine and there are no others on the market, for the simple reason that Festool has patented it. It will be at least a decade until other manufacturers can copy the core domino cutting mechanism.

However, there are some machines that do some of the things the domino can, but they can’t do it all. Biscuit jointers are a good alternative for joining and aligning boards. But they can’t create mortise and tenon joinery in thick stock.

Doweling machines, even a really good one like the Mafell Duo Doweller, come close (and can also be used for things the Domino can’t, like shelf pins), but lack a bit in strength and are not very forgiving as the pins need to be dead accurate.

The other choice is whether you should go for the Festool Domino DF 500 or the XL DF 700. The 700 is bigger and slightly more developed. It can make bigger mortises than the 500 (up to 14 mm), but with the Seneca adapter it can also use the small bits of the 500.

So the 700 can do everything the 500 can, and more. Easy choice then right? However, the 700 is much cunkier and not so comfortable to use (especially on smaller pieces) as the 500 and a lot more expensive. If you don’t need the big mortises of the 700, then the 500 is probably the better option.

I usually work with solid wood, so other than a few small plywood projects, I’ve pretty much exclusively used the domino as a replacement for mortise and tenon joinery. Below are a few of the items I’ve made with the domino.

Small bench no. 1, Ash frame, Oak top.

Small bench no. 2, Maple frame and top.

Desk, all Maple. The top bars are connected with hand cut joinery, but the bottoms are all connected with dominos.

If you hadn’t guessed it yet, I really like the Festool Domino. It has many fans and some even call it the best invention in woodworking. I wouldn’t go that far, but it is fair to say that it is a unique machine.

It does not do anything completely new. Loose tenon joinery existed before the domino, and can be done with a regular router or mortiser. What it did bring is extreme convenience and speed.

For hobbyists, I think it’s a great machine for those who prefer to focus more on the design and building part, and less on technical joinery skills.

For professionals, it’s almost a must have, simply because it is so much faster than other methods of small-series joinery.

There is no shame in using a tool like this – it is not cheating. Even the Japanese master woodworker Ishitani uses the Domino now! If that isn’t proof of the value of this machine, I don’t know what is.

I bought my Domino 500 Q-Plus at Rubart.de, which I think is one of the best places to buy it at in Europe. They have some of the lowest prices for Festool products, but still have a good reputation and fast delivery.

These are also some good places to buy the Domino 500:

Tip: When comparing prices, do note that there are different packages that include either just the machine (Q-Plus), the machine with accessories (Q-Set), or even with a selection of dominos included.

What do you think of the Domino 500? Is it really an essential tool in any woodworking workshop? Let me know in the comments below.

© Machine Atlas 2025

There are no comments yet, be the first to leave one!

Every comment on MachineAtlas is read and answered. And if you know some useful info or tips, please share them. You could really help out some fellow woodworkers!