How good is the Veritas Router Plane? Find out in my review after using it for more than 6 months

I bought the Veritas Router Plane about 6 months ago. After using it in quite a few projects, from building a desk with hand made joinery, to laptop stands and small benches, I thought it was a good time to share my experiences with this tool.

The Veritas comes with the following parts in the box:

The Veritas router plane’s design is based on the classic Stanley #71, but is a bit more refined. While the Stanley 71 existed with both an open and closed mouth (actually called the Stanley #71 1/2), the Veritas only has a closed mouth design.

The advantage of a closed throat is better support on the workpiece, while the open throat allows more visibility on where you are cutting and you can get a bit closer to the edge. On the Veritas however you can turn the blade around and use it as a bullnose as well, so you get the best of both worlds.

There are two holes in the cast iron body, which allow you to screw a wooden support piece underneath. This is helpful if you need to span gaps that are larger than the plane is wide.

The Veritas router plane comes with two standard blades, a 1/2” regular straight blade, and a 1/2” V-shaped blade for getting into tight corners. Veritas also sells several smaller blades, both in metric and imperial sizes.

The only optional accessory available is a metal fence, which can help when you want to cut thin grooves along the edge of a board. It can be useful, but is definitely not an essential part of this router plane.

A classic problem of router plane blades is sharpening. Sharpening them the traditional way, as has been done with Stanley router planes for a century now is quite tricky. Paul Sellers made a video about it, but you can see that even for him it’s not the most comfortable iron to sharpen.

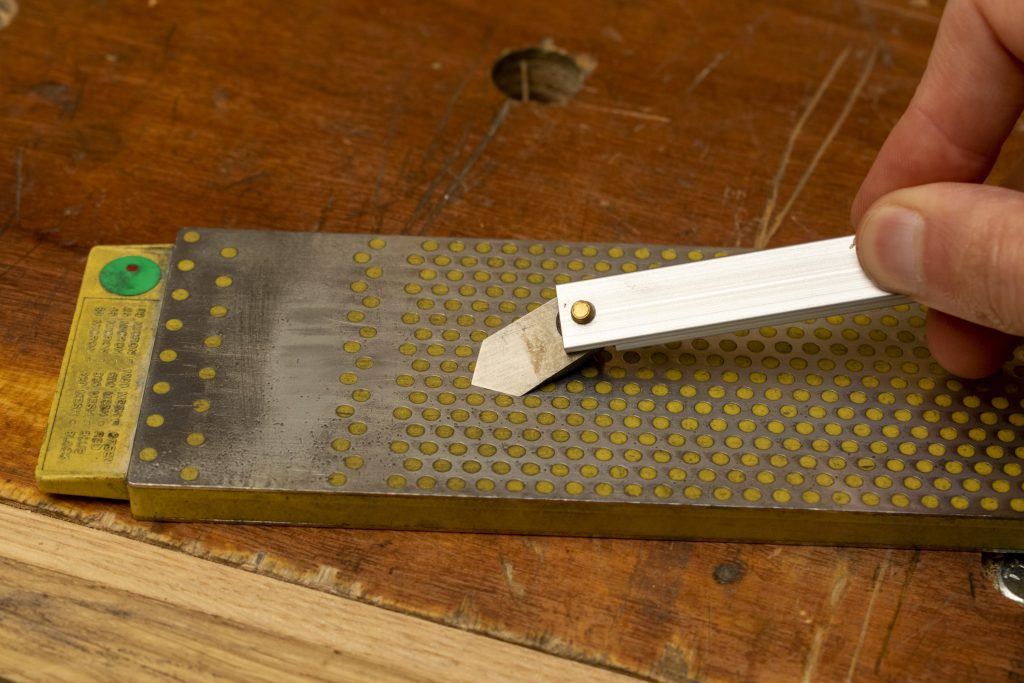

Luckily, Veritas has come up with a simple, but very useful solution. They’ve made a special metal bar to which the plane iron can be screwed, so it is no longer in a 90 degree position, but rather in a 180 degrees position like regular plane blades. This is possible because the iron is no longer one piece, but a metal bar with the iron screwed on to the bottom.

It’s still a little finicky to sharpen, but much easier than the 90 degrees classic router plane blades. It is also unique to the Veritas, as the Lie Nielsen router plane does not have such a system, which I think makes the Veritas much more attractive.

As with almost all Veritas products, the build quality is excellent. The main body is made from cast iron, and is very sturdy and heavy. The handles are made from maple, although this is not always the case, and there are versions with other kinds of wood. The knobs for the height adjustment are made from brass and have small ribs which makes them tactile and comfortable to use.

The wood used for the handles can be a little on the soft side. I managed to drop a ruler on one the first day I got the router planer, which left a small dent in the finish. The finish doesn’t go all the way through (it’s a surface funish, not a penetrating one), so if you do damage the handle due to clumsy behavior like mine, the dents will remain quite visible.

When you first get the plane, you’ll need to clean the cast iron base and protect it with light film of oil, as per the instruction manual. I failed to do so, and quite quickly a dark pattern emerged on the bottom of the plane body, so protecting it with some oil is actually essential.

Aside from these small issues (which were entirely preventable), I have not had any problems with the materials used, and the build quality can be described as simply excellent. The handles feel really smooth and comfortable to the touch, and the brass knobs are very tactile and comfortable to use.

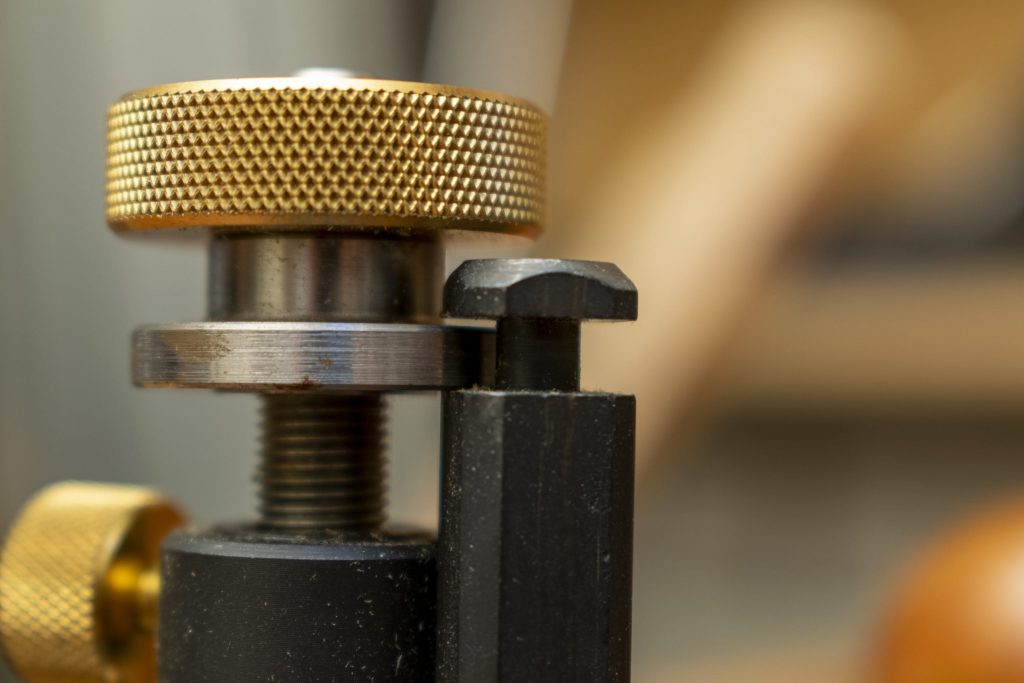

The depth of cut can be adjusted by loosening a knob, and then turning a knob on top of the plane to move the iron up or down. There is also a special collar that can be locked at a specific height to prevent the iron from moving any lower. This is particularly useful if you want to make several cuts of the same depth.

The system works quite well, but there are two small improvements that I hope Veritas will make in the future.

My first minor point of criticism is that the knob to secure the iron, to keep it from moving, is a bit hard to tighten. You really need to turn it strongly all the way at the end to make sure it’s truly secure. I’ve had a few occasions where I thought I had it tightened all the way, but then while cutting it actually came loose again.

A second point is that the height adjustment knob has some extra space. This means that when you just lowered the iron, and if you now what to take it back up, the height adjustment knob will have to be turned a few times before it makes contact with the iron again.

I think this is a design choice, but I’m not entirely sure what the advantage is (if you do know, please let know in the comments). The thing is that usually when you’re cutting, you want to turn the knob only a half turn or so to change the depth of cut.

But if you change direction (so from lowering to raising or from raising to lowering), you need to turn it a few more times before it takes effect, due to the extra space. I found that I sometimes forgot about this, turning the knob only half a turn, then finding that it had not actually changed the plan iron’s height.

I’m probably nitpicking here, but it’s a small design decision that I think could be improved. Overall the height adjustment systems works great.

I use this router plane in almost every project I make. The most common use case is evening out the bottom of dados and grooves, for which it is the perfect tool. Another thing I often use it for is flattening the cheeks of tenons. With a simple technique, which I learned from Paul Sellers, you can make sure the tenons sides are perfectly flat, and the tenon itself is located exactly in the middle of the piece.

I’ve used the plane in both softwoods and hardwoods like hard maple and oak. Compared to my previous wooden router plane with a not-so-great iron, the Veritas is like cutting through butter. Obviously if you use it on oak or maple, you’ll still have to sharpen it regularly to maintain a smooth finish, but it really did a great job and I did not come across any types of wood it couldn’t handle.

All in all, I can say the Veritas Router Plane is a great tool, and one of the favorite ones in my workshop. I mentioned a few minor downsides, but these are really not that important and overall the plane is a pleasure to work with. The build quality and ergonomics make it comfortable to use even for longer periods of time.

Given the advantage of the sharpening system over the Lie Nielsen and the fact that vintage Stanley router planes currently go for the same price as a new Veritas one, I think the Veritas is by far the best option when you’re looking to purchase a new router plane.

These are some good places to buy the Veritas Router Plane. I bought mine from Fine Tools in Berlin.

What do you think of the Veritas Router Plane? Let me know in the comments below.

© Machine Atlas 2026

A deliberate allowance for backlash in screw type adjustment devices may help thermal expansion of metal during use from shifting the blade height. As we know friction between a tool and wood interface develops significant heat and cast iron has excellent heat transmission properties.

Thanks Phillip, that seems like a very plausible explanation for the gap. I didn’t know that thermal expansion could even be an issue in hand tools like this. But it makes sense as chisels, saws, and planes can get quite hot if you’ve worked them hard for a few minutes.

Hi why do they make it out of strong ductile iron then use cheep flimsy alloy for the blade clamp. Plus depth stop screws directly onto a threaded rod which in time would damage the threads. Nobody else seems to have noticed the flimsy blade clamp brass or steel or iron would be better. Tony

Hi Tony, those are interesting observations. I’m not sure about the blade clamp as it doesn’t seem too flimsy to me, I’ve also not had any issues with it.

Regarding the depth stop, screwing straight on the threaded rod doesn’t seem ideal. But the depth stop thumb screw is made of brass, so I don’t think it will damage the threaded rod, which is of a harder material. In the long run the depth stop screw itself may get a bit damaged (softer brass), but that’s easier to replace than the threaded rod itself.

Rob