A look at a very interesting new type of woodworking machine made by a Korean inventor.

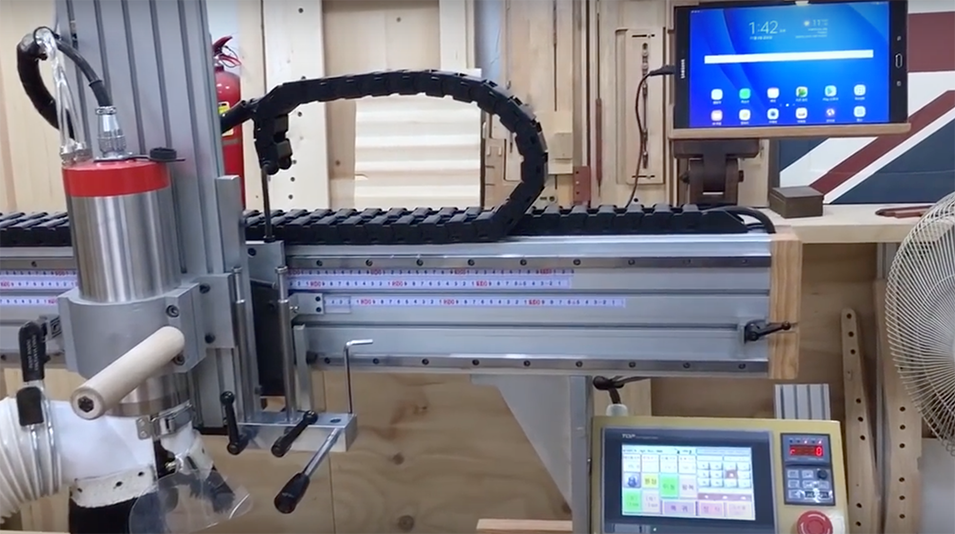

At first glance it may look like a CNC machine. It has a spindle attached to a gantry, which is controlled with a computer that makes it go up and down. But it actually isn’t a CNC machine. It’s an inventive machine developed by a Korean woodworking business, which can do many different things.

Its main advantage is that you don’t have to spend hours setting up the code, designs, and tweaking the cutter speeds, amount it takes off etc. which you have to do with a true CNC machine. For many one-off tasks this is very inefficient. With the Multi Wood Machine you can have the precision and functionality of basic CNC tasks, but the speed and ease of use of a normal hand-held router.

The Multi Wood Machine is developed by the Korean company Woodro Leehyun Co Ltd. It is currently only available in Korea, but they do have plans to export it as well.

In this article, we’ll take an in-depth look at this interesting new machine, and try to find out how useful it really is.

The Multi Wood Machine has two basic tools: a spindle and a circular saw. We’ll briefly look at the saw functionality as well, but the spindle router really is the core of the machine.

The spindle on this machine is identical to the spindles found on CNC routers, which in turn are very similar to hand-held routers used by most woodworkers, but controlled by a computer instead of by hand.

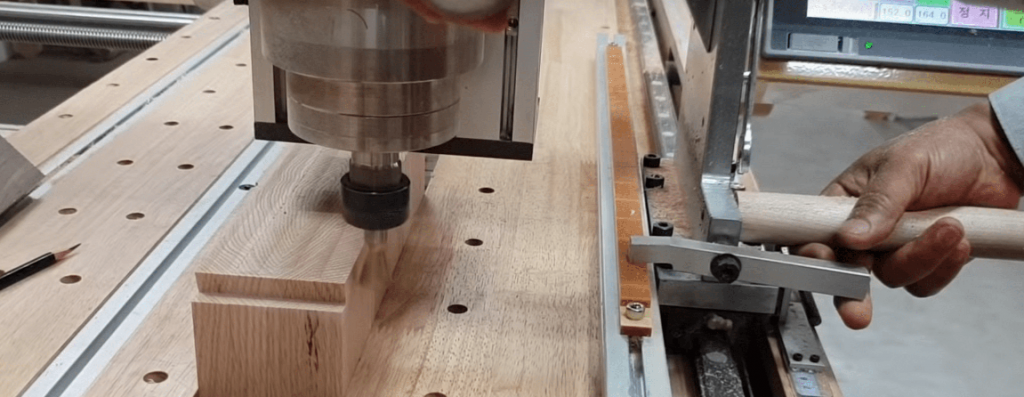

The special thing about the spindle of the Multi Wood Machine is that it is part computer-controlled and part hand-controlled. The Z-axis (height) is moved electronically by a computer and motor, while the horizontal axes (X and Y) need to be moved by hand.

The overall frame of the machine is similar to that of a CNC machine, with a gantry moving over linear rails (Y-axis) and the spindle moving along the gantry (X-axis), also on linear rails. Normally, a belt or screw drive is used to move the spindle and gantry electronically, but with the Multi Wood Machine this is done by hand.

The different axes can be locked in place, or limited to a specific range by setting stop blocks. This allows you to rout a straight line, or rout out a specific area (for example a square).

Besides the basic stop blocks and locking an axis in place, Woodro has also designed various guides to use with the Multi Wood Machine. These allow you to rout specific shapes, such as tenons or dovetails, and make sure distances between cuts are evenly spaced.

This is an area where I think the Multi Wood Machine shines, because it is relatively easy to set up the machine, and once everything is in place, you can quickly rout many pieces in one batch.

Box joints and dovetails are cut in similar ways. Along the Y-axis there is a rail to which a guide can be attached. This guide has small gaps and blocks, evenly spaced, with exactly enough room to allow for a handle to fit in there. The handle, which is attached to the moving gantry, can be easily moved up and down, locking it in and releasing it from the guide.

When used with the correct router bit, this allows you to create perfectly spaced dovetails and box joints, which are guaranteed to fit together. You can even use multiple boards clamped together and rout them all in one go.

You can see how Dovetails are routed by the Multi Wood Machine in this video.

To cut tenons on the Multi Wood Machine, a more classical guide is available. This guide is similar to templates found on machines like the Leigh Mortise & Tenon Jig or the Pantorouter.

The workpiece is secured vertically, and the guide is placed on the rails at the right location. An iron bar, which can be moved up and down, and slightly along the X-axis, then follows around the guide. This makes sure that all material except the tenon itself is removed.

In most of the Multi Wood Machine videos this is only shown in use, without the actual set up. This is a bit deceiving, because although the results are very good, most of the time goes to setting the guide and iron bar in the right position. To its benefit, this is also the main downside of other similar mortise & tenon jigs.

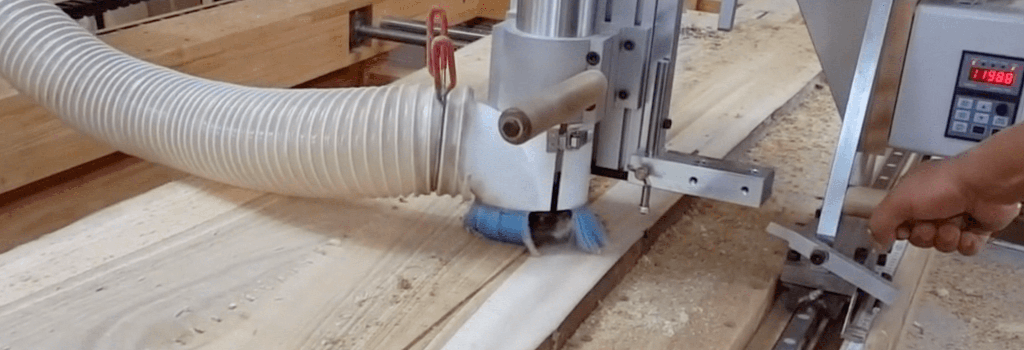

Another useful feature is the flattening of large boards. This works similarly to a jig that many amateur woodworkers use when they need to flatten a board or slab that is too large for their jointers. The board is secured in place, and the router is moved across the board at a fixed height, making it the same height everywhere.

This is done using a flattening bit, which is much wider than normal router bits. Because this machine is quite powerful, but moves around much more efficiently than a hand-held router, this can be done relatively quickly and easily.

It can be tempting to use this method for smaller boards as well, but it is quite a bit slower than jointing, so not the most efficient way to go about it. If you have a board with switching grains or many knots however, the flattening method may still be preferable to jointing to avoid tear-out.

This method can also be done on a CNC machine, but once again you can save some time setting your machine up.

You can see the flattening process in process in this video.

The last spindle feature we’ll discuss is circle cutting. In contrast to most other techniques, the spindle is actually stationary (although it may be moved up and down the Z-axis to avoid taking off too much in one pass).

To cut perfect circles, Woodro made a jig that is already used quite a lot on a band saw, where the workpiece is secured in the middle, so it can rotate around the center. The middle is placed at the desired radius distance from the router bit.

By rotating the workpiece, while the router bit is cutting, a perfect circle can be achieved. The advantage compared to the same procedure on the band saw is that you don’t need to cut inwards from the waste side of the workpiece. In fact, there is no waste side at all. This makes it useful for cases where you don’t need the inner circle itself, but the round hole in a specific workpiece.

You can see the circle cutting jig in action in this video.

As mentioned earlier, besides the spindle, there is also a circular saw attached to this machine. In their videos, Woodro show multiple machines, and not all of them include circular saws. This is already an indication of how important the saw is to the overall machine.

The saw is simply a modified version of a DeWalt chop or miter saw, which can be pulled down from the gantry to the worktop. Just as the Multi Wood Machine could be seen as a reverse router table, the saw can be seen as a reverse table or panel saw. Instead of moving the workpiece, the saw is pulled along the piece.

Safety experts and officials are a better judge, but the safety of this contraption seems somewhat dubious to me. These modified mitre saws are designed for cross-cutting and not for ripping. Combined with the fact that normally the saw blade is embedded in a heavy table, this makes you wonder what happens when a board with a lot of wood movement starts to pinch the blade. Will the saw break before the workpiece does?

See the saw at work in this video (starts at the action).

Since most of the time on the Multi Wood Machine the spindle moves, and the workpiece is stationary (the opposite of a router table), making sure materials are properly clamped is essential.

To do this, Woodro has built what is basically an enormous vise into the center of the frame. In the middle of the frame is a jaw, which runs over two sturdy spindles. These spindles can be controlled electronically (both speed and distance) via the touch screen, making it easy top operate. This allows you to clamp workpieces on both sides of the frame.

On top of the jaws of the giant vise are many small dog holes in which holdfasts or bench dogs can be placed. There are also two t-tracks in the middle that make it possible to use regular clamps as well.

There is also a system to put a small plateau on sides of the vise jaw, which helps in setting pieces at the same height every time. This is essential for when you want to rout multiple tenons at the same height.

Woodro is continuously improving on their design, and regularly releases videos of new features on their youtube channel. The latest addition is mounting a lathe on the frame of their machine. I’m not entirely sure how much of an improvement this is over CNC lathes or normal lathes in terms of efficiency, but the end results look solid.

Most functions on the machine, like moving the spindle up and down, or moving the vises back and forth are done via the touch screen that is attached to the gantry.

Besides the control touch screen, there is also a tablet screen, a little higher. There are also many instruction videos available on this screen. It is Woodro’s philosophy to try to help and educate woodworkers to use their machine. Having instructional videos right at the machine seems like a smart strategy. Especially with a new machine where people are not familiar with how to use it, good explanation and education is paramount.

We can safely conclude that Woodro’s Multi Wood Machine is an interesting concept, with many different features. But how useful is it in practice?

Let’s first look at its advantages compared to existing machines. Compared to a CNC machine, the main advantages are that you do not need to make designs, create g-code, and other time-consuming set up tasks. For many tasks, you don’t need the extreme accuracy of a CNC machine, and hand measurements will do just fine.

It is also a great alternative to several jigs, like box-joint, dovetail, mortise & tenon, and circle-cutting jigs. While those jigs only have a single purpose, the Multi Wood Machine can do all of them, and nearly equally as well.

Of course, the Multi Wood Machine cannot do everything. It lacks the ability to create the refined and detailed cutouts of a CNC router. It also has one major downsides compared to existing jigs: its size. The Multi Wood Machine is large, and takes up more space than the average woodworker’s shop in its entirety. But for those who have the space, and the use for it — small to medium scale professional wood shops — it can be a useful addition.

One potential issue with a newly developed machine — or any new invention for that matter — is that its reliability is unknown. Most products go through many iterations and rounds of improvements to get to a state in which they are reliable.

For example, the Multi Wood Machine’s frame is largely made of wood. It is not unthinkable that in 5 years time, the wood may have gone out of shape. Even only bending 1 or 2 centimeters would make any measurements no longer reliable, which is disastrous for a precision machine like this.

If you look at Woodro’s channel a bit more closely, you can see that the inventor is very proud of his creation. This is a great thing, because it means he will do everything he can to make it a great product. But it can also be a pitfall, because it can be hard to look objectively at something you love.

The result is that he tends to use the machine for nearly everything, even when it is not the best decision. A panel saw is better at cutting large boards, and a jointer is better at flattening boards that are not too wide.

The trick with this machine is therefore to use it for the cases where it makes sense to use it, and where it really gives you an advantage, and not try to make it do everything (which can be tempting if you have a shiny new machine you love). If you use it right, it can be a great addition to any small to medium-sized production workshop.

© Machine Atlas 2026

how can i learn about this machine, price and bring it to Israel

I think your best option is to contact Woodro Leehyun directly via their website (http://woodroleehyun.com/). I sent them an email before with some questions for this article, and they respond quite quickly and were very friendly.

good day I would like to know about the price of this machine and the shipping

Can I purchase this machine?

Or do I build this machine?

What is the price for ether?

Can it be shipped to the United States?