What to look for in second-hand machines, and how to find a good deal.

So you’ve narrowed down your search and know which woodworking machines to consider, and have actually found some potential vintage targets. How do you know this specific one is right for you and you’re not buying a broken machine?

We’ll give you a basic overview of the most important things to look for when considering purchasing a second-hand woodworking machine. First, we’ll look at the things you can do before you go and check out the machine (this is the first tip: Never buy a machine without seeing it in person!).

The key thing to do before seeing the machine is to do proper research. How will you know if parts are missing when you don’t know what all the parts are? This doesn’t mean you have to know every nut and bolt, but if you know the key parts of the machine and what they look like, you’ll feel much more comfortable making a purchasing decision.

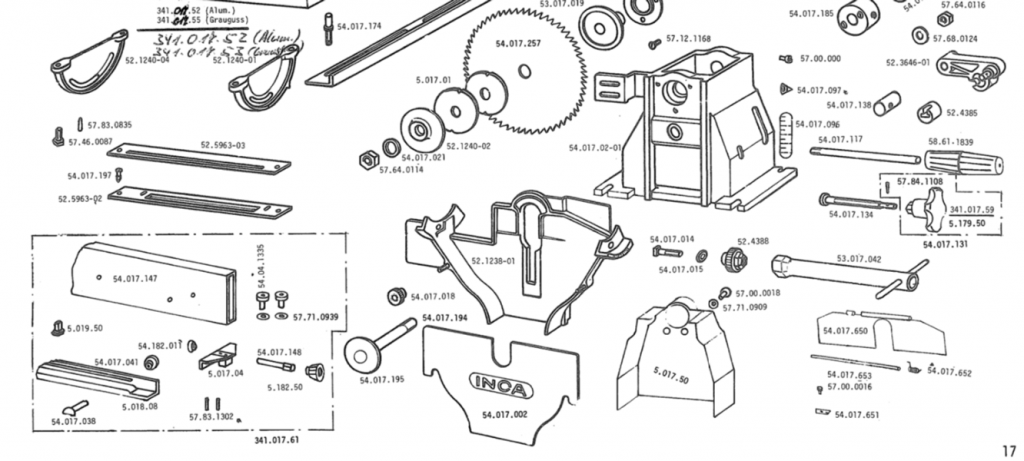

In 90% of all cases there will be a manual available online for your chosen machine, which can usually easily be found by simply searching for [machine name] + manual on google (surprise!). The great part about these manuals is that they’ll often have drawings of all the parts.

Check this out for a few minutes and you’ll quickly see all the key components. Does the table saw have a riving knife? Does the radial arm saw come with a cover for the saw? Does the jointer-planer come with a dust hood? Looking at Youtube for videos of the machine in action can be very helpful as well.

Another useful thing to check is to see if there are any extra attachments or options that could come with the machine. These can be of great influence on the price, and you can also use them as an argument when bargaining.

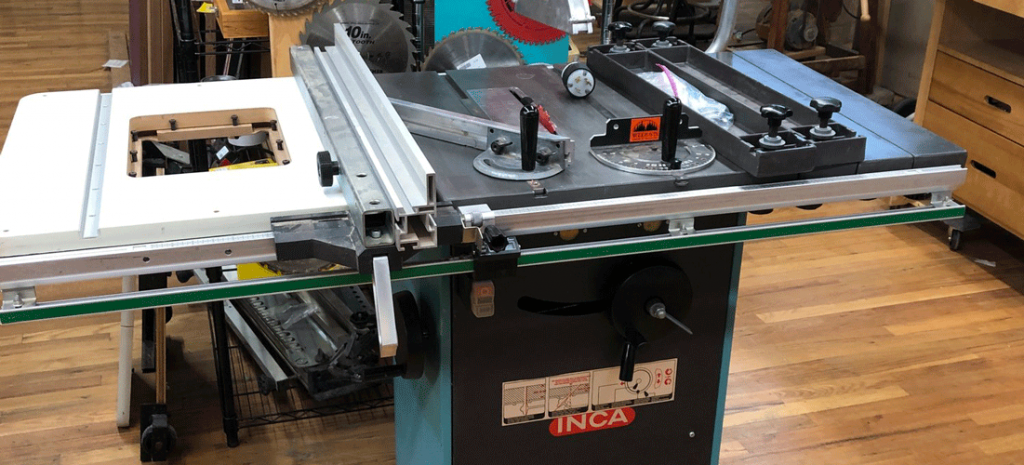

One of the biggest problems when refurbishing old machines is the potential lack of replacement parts. That is why it is very useful to check whether any missing parts can be replaced. In some cases online stores still sell parts (for example for the Elektra Beckum HC260), or there is a second-hand market in parts (for example for many Inca machines), but sometimes they are nearly impossible to find.

Often you can see from the images with the ad that some parts are missing. Maybe the seller even lists the missing parts explicitly. It is recommended to check whether these parts are essential, and if so, whether replacement parts are available before you go and see the machine. If they are not essential, you might be able to get a better deal.

You’ve done your research, and now you’re going to see the machine in person. What should you look for? The two key things to look for are whether the machine has all essential parts that cannot be replaced, and if it has any defects that are unrepairable.

The first question is relatively easy if you’ve done proper research. Simply see if it has the key components that are necessary for operating the machine well and safely. Remember to take into account that some parts can be simply ordered online.

Looking for potentially unrepairable defects can be trickier, and will often require you to bring tools. What counts as irreparable defects differs for each type of machine, but some common examples are bent arbors that cause a wobbly saw blade or planer knives, and jointer tables that are not flat.

If jointer tables are warped or bent you will never get a flat board, no matter how good a condition the rest of the machine is in, and it cannot be repaired easily. So if you know you’re going to check a jointer, always bring a straightedge to check the flatness of the tables.

Always have the seller turn on the machine for you, and preferably take some wood with you for a test run. Many serious defects can only be found when actually using the machine. If the seller refuses (or has some excuses) to turn on the machine, consider this a red flag. Never buy a machine without having seen it in use!

Examples of things that can be repaired are loose or missing belts, bearings that don’t run smooth anymore, and rusty and blunt blades or knives. These problems can be solved, but they may be an indication that the seller has not always taken great care of his or her machine.

Of course, some missing parts or defects may not be unrepairable, but you might still not want to go through the effort of repairing them if it is difficult and a lot of work when there are perfectly fine alternatives available. Still, most of the time the only way to find a bargain is if you are willing to put in some extra work yourself.

Extra tips: Do not forget to check whether the machine and motor run on a voltage that you have at home. Quite a few machines run at

380/400 volts, because that is what most companies use, but not everyone has that at home. If you do have the electrics set up for 400V you may be able to find a nice bargain, since those machines tend to be slightly cheaper than the standard single phase ones.

Now that you’ve determined the machine is in a good condition, and you’re able and prepared to do the necessary repairs (if any), the only question that remains is that of money: How much should you pay?

People will tell you there are a ton of tricks to negotiating, especially with vintage items. But the reality is that 80% of the work is knowing what the machine is actually worth. Without knowing what the average going price is, you’ll never know where to start negotiations and you’ll never know if you actually got a good deal.

That is why during your search online and your preparatory research you should take note of what price most machines are listed for. That way you’ll know when a seller is being unfair and when you’re looking at a bargain.

We usually try to open by asking the seller for their target price (never ask for someone’s lowest price! This will only offend them), which already gives you a lot of information. If this target price is way above the average price, you might want to back away, and if his or her target price is much lower, you know you’ll have to act quickly.

In our experience, machines often come with accessories, such as a mortising table or even a dust collection system. You can sell these on and as such you should take their sales value into account as well. For example, we once bought a vintage jointer planer for about the average price on the market, but it came with a mortising table and a dust collection system, which we were able to sell for €100 (~$110) each, actually making it a bargain.

Just as there are potential gains from the extras, you should take into account all the costs you might have to make to get the machine up and running. Make an estimate of how much you will need to spend on new saw blades, sharpening knives, and replacement parts. These costs can be quite significant and turn what seemed like a good deal into quite an expensive one.

Don’t be deceived by dirt. Dirt is actually a great thing, because many people are risk-avoidant and prefer to only buy second-hand machines that look like new. The reality is that what a machine looks like often has no connection with its actual quality. Dirt can be removed relatively easily with the right materials. So, if you want to get a great deal on a second-hand woodworking machine, find one that’s a bit greased up and dirty, but complete. It will scare many potential buyers away, potentially leaving you with a great machine for a low price.

Not all parts are shown in the ads! Often people just take a quick picture of the machine they want to sell. Maybe they inherited it, maybe it’s been sitting in a shed for 30+ years. Quite often sellers are no experts themselves. If you can find out that there’s more to a sale than what’s pictured (by calling or messaging the seller), you are a step ahead of other bidders and a step closer to finding a bargain.

Hopefully this guide has helped you with buying second-hand woodworking machines. If you have any suggestions or tips about what to look out for when looking at woodworking machines, let us know in the comments!

© Machine Atlas 2026

I have a factory full of woodwork machines in Pretoria that I want to sell. Can you bring me in contact with potential buyers or are you interested?