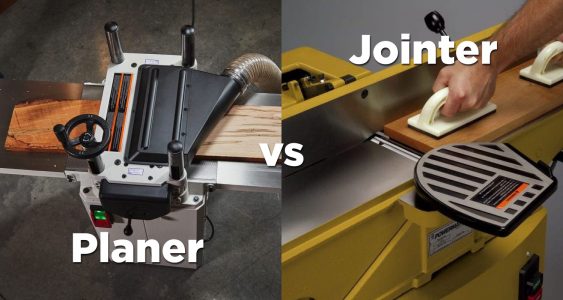

What’s the difference between a jointer and a planer? And why do US and UK woodworkers use completely different names?

Some woodworking terminology is simple: a table saw is a table with a saw blade sticking out of it. But then there are some terms that just don’t seem very logical, especially when different countries use conflicting names as well. This is the case for (what Americans call) jointers and planers.

Both tools plane wood (like a hand plane does) and create shavings, but only one of the two is actually called a planer. To confuse things even more, what is called a jointer in the US is traditionally called a planer in the UK. So the terms are completely switched around on either side of the Atlantic.

So let’s step back from the specific terms for a moment, and first describe the tools in terms of functionality (using the US names).

The jointer is used to create a perfectly flat surface on one side of a rough board. It can also be used to create a second perfectly flat edge at 90 degrees to the first flat surface.

The planer on the other hand is used to create a second surface that is parallel to the first one. It brings boards to a specific thickness. What it cannot do is put a guaranteed flat surface on any side of the board. The planer simply copies the opposite side’s surface. If the other side is flat, then the planer will create a perfectly flat surface as well. If the other side is wavy, the side planed by the planer will also be wavy.

By using both machines together (first the jointer, then the planer), you can create perfectly flat and square boards with a specific thickness. But neither of the two machines can do this alone.

Getting back to the terminology, the word planer (in the US) is actually short for thickness planer, which is a lot more descriptive. As I just explained, that is exactly what a planer does – bringing a board to a specific thickness. In the UK, because they use the word planer for the jointer, they call a thickness planer a thicknesser.

There are also machines that combine jointer and planer functionality in one. These are called jointer planer combos in the US. To confuse things even more, in the UK these combination machines are called planer thicknessers. Both names make sense if you know the local names for the separate machines.

But the fact that in the US there is a thickness planer (planer), while in the UK there is a planer thicknesser (jointer planer combo), and those don’t refer to the same machine at all is definitely confusing.

To summarize the different terms used in the US and UK:

Now because of American dominance on the internet, the US terms are much more common. So if you want to find info about a specific machine, using the terms jointer, planer, and jointer planer combo are your best bet. But it may be helpful to keep the UK terms in mind whenever you’re searching a UK forum like UKWorkshop, or when listening to a UK woodworker on youtube.

In order to get a board that is perfectly flat, square, and at your desired thickness, you will need both a jointer and a planer. So getting two machines, or a jointer planer combo is generally the best idea.

But if you only have room or the budget for one of the two machines, which one should you get? For me, the answer is simple: get the planer first.

Getting only one of the two machines means you will need to replace the other machine’s job with a hand plane. Doing the jointer’s job with a hand plane, namely creating one flat surface is far easier in my opinion than getting a board perfectly to thickness with a hand plane. Using a Stanley 5, 6, or 7 (or equivalent) it is not very difficult to get a board flat once you’ve got the basic technique down. Andrew Klein made an excellent short video showing this technique of combining jointing with a hand plane together with a power planer.

In contrast, to get a board to perfect thickness by hand, you have to scribe the height all around with a marking gauge, and make sure you plane off exactly to the line. This is quite a precise and tricky process. Another downside is that if you want to take off a large amount, it will be a lot of work using a hand plane. When jointing, you’re always only taking off a little bit of the top surface. Check the video below by Paul Sellers, who shows how to plane a board to thickness with a hand plane.

Additionally, using a planer sled, you can turn a planer into a makeshift jointer. Although not as easy to use as a separate jointer, it does work. The opposite, using a jig to turn a jointer into a planer, is not possible.

So in short: The jointer can be quite easily replaced with a good hand plane or a planer sled, especially for hobbyist woodworkers. Doing the planer’s task by hand is much more work. So I would recommend getting a planer before you get a jointer.

Both jointers and planers can be upgraded with spiral cutterheads, which have many advantages over traditional straight blades. If you’re considering upgrading, or simply want to know what benefits a spiral cutter has, check out my guide to spiral cutterheads.

© Machine Atlas 2025

There are no comments yet, be the first to leave one!

Every comment on MachineAtlas is read and answered. And if you know some useful info or tips, please share them. You could really help out some fellow woodworkers!