Looking for a new jointer? We take a close look at JET’s 6 and 8-inch long-bed jointers to find out what makes them special.

JET’s jointers are a popular choice for both hobbyist woodworkers and small professional workshops. They offer a tried and tested cast-iron design of solid quality for a reasonable price. However, JET makes four jointer models and the differences between them are not always obvious.

We will take a look at each of the four models to determine how they are different, which ones may be better or worse, and which machine may be right for your specific situation.

JET makes two 6-inch jointers, the JJ-6CSDX and the JJ-6HHDX. They are identical, except for the cutterhead. The standard model, the JJ-6CSDX, has quick-set straight knives, while the JJ-6HHDX has a helical cutterhead installed. The Helical Head model is more expensive (~$300 at the moment).

We’ll first look at the specs and features of both machines and then go on to compare the cutterheads to find out whether the upgrade to the Helical Head is worth it.

The jointers have extra long cast iron infeed and outfeed tables. JET actually calls them ‘long-bed jointers‘, which helps to contrast them with older JET models which were quite similar but had shorter tables. Longer tables help significantly with keeping long workpieces perfectly flat.

The tables are mounted to the frame with a classic dovetail (also called wedge-bed) system, which means they slide at an angle over a dovetail shaped extrusion. This is a classic design already used for many years throughout the industry.

There is a minor disadvantage to this dovetail design, which is that it can start to wear slightly over time, making it harder to set the two tables in one plane. However, this wear will take a long time and even then it is questionable how big an impact it will have. However, if you do not want to take this risk, take a look at jointers with a parallelogram base design.

One unique feature of JET’s 6-inch jointers that is not often seen elsewhere is the way the tables are raised and lowered. JET calls it ‘front-mounted table adjustment’. For both the infeed and outfeed table there is a chrome handwheel mounted on the front, rather than below the tables. This makes it easier to reach in and comfortably change the height of the tables.

On some jointers or jointer planer combos the fence can be a bit flimsy, and manufacturers seem to think of it as an easy component to save costs on. However, if you want to joint accurate 90-degree edges on your boards (which is really an essential feature of a jointer) you need a solid fence.

Luckily JET provides sturdy fences which are secured well in the middle. The fence has 3 positive stops for 45 degrees left and right, and 90 degrees. This allows you to much quicker get the right setting, whether you want to just create a straight edge or joint miters.

The guard used on the machines is a classic American-style spring-loaded pork-chop cutterhead guard that moves out of the way when you push against it with your workpiece. It will depend on your personal preference whether this is a good or a bad thing (compared to a Euro-style blade guard for example).

The machine also has a rabbeting ledge, which is not frequently used by most users, but it is a nice additional feature to have.

JET’s 6-inch jointers run on 1 HP motors, which is not overly powerful. One might say they are even on the weak side, but given the maximum jointing width of only 6-inches, it doesn’t need to be too powerful anyway. However, you may find that you need to keep your blades sharp to maintain enough power to joint hard and difficult boards.

On to the differences then. As mentioned before, the cheapest model, the JET JJ-6CSDX, has quick-set straight blades, while the JJ-6HHDX has spiral cutters. How do they work and is the upgrade worth it?

The quick-set blades of the JET JJ-6CSDX are similar to the standard classic straight knives found on many jointers — 3 straight knives that need to be set at the same height.

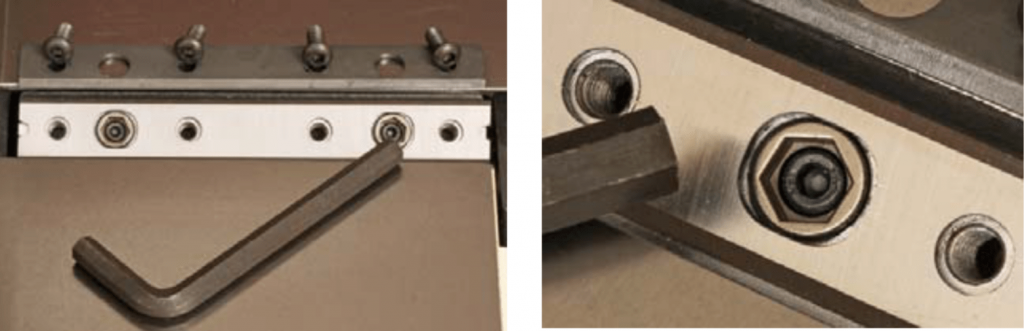

However, JET’s quick-change design (see the images below) has a special nut that can be used to lower or raise the blades. Because each blade has identical holes, if you swap out the blades it will set itself in exactly the same position as the previous blade.

The result is that you only need to set your blades to the right height once. When you’ve done that, each time you change the blades you can just lock them into place without any adjustment needed. This is a great time (and annoyance) saver. Each blade has 2 sharp edges, so you can flip it over when one side gets dull.

Helical or spiral cutterheads have many different carbide cutter inserts instead of three straight knives. These cutters are positioned in a spiral shape around the cutterhead. Each cutter can be loosened individually and has four sharp sides.

This system has a several useful advantages: Jointing makes less noise, the jointed surface looks better, the cutters are easier to replace when damaged or dull, and last much longer.

Because each cutter can be loosened and replaced individually, if you hit some metal, you only need to replace one cutter instead of the entire blade. Also, because they have four sides, you can just turn them 90 degrees when they get dull. This allows them to last much longer than classic straight knives.

Helical Heads are also better at dealing with difficult grain and generally give better results. They also do not need any adjustment, unlike straight knives, although JET’s quick-change system solves that problem as well.

The question is, because the quick-change blades are already a good upgrade over standard ones, do you really need the spiral cutters at a 30% extra cost?

We would still recommend the upgrade, because as mentioned before, there are so many advantages to helical cutterheads. The price difference, even if pretty high in percentage terms, in absolute terms is quite small, especially compared to other machines where it can cost 2-3 times as much to upgrade to a helical head.

Combined with potential cost savings of less frequent replacements, the difference becomes even smaller. This makes the upgrade well worth it in our opinion.

If you would like more information about JET’s 6-inch planers and see them in action, check out these reviews on Lumberjocks or the video by Dave’s Woodshop below.

JET also makes two 8-inch jointers, which again are identical except for the style of the cutterhead. The JET JWJ-8CS has standard straight knives, while the JET JWJ-8HH has a helical head. The upgrade costs in the region of $500.

Unlike the standard 6-inch model, the 8-inch standard model does not have quick-change knives. This means you will have to set up the knives in the classic way every time you change them.

The two 8-inch models are very similar to the 6-inch ones and have all the same features. The only design difference is that the handwheels to raise and lower the tables are located underneath rather than on the front.

The 8-inch models have a more powerful 2 HP motor and longer (1830 vs 1422mm) and wider tables than their smaller siblings.

To read a detailed description of all features and components of the 8-inch jointers, scroll up to the introduction of the 6-inch models.

Type of machine

Jointer

Designed in

United States

Manufacturer

JET

Production status

New

The JET JWJ-8CS has classic straight knives which all need to be set to the same height and level with the tables. This is a relatively time-consuming and (to some) annoying task, which needs to be repeated each time the blades are taken out to be sharpened or replaced.

It is a bit strange that JET offers the quick-change system (which we think is a major upgrade) on their standard 6-inch model, but not on the standard 8-inch jointer. Maybe they will add it in the future, but currently it is not available.

Helical or spiral cutterheads have many different carbide cutter inserts instead of three straight knives. These cutters are positioned in a spiral shape around the cutterhead. Each cutter can be loosened individually and has four sharp sides.

This system has a several useful advantages: Jointing makes less noise, the jointed surface looks better, the cutters are easier to replace when damaged or dull, and last much longer.

Because each cutter can be loosened and replaced individually, if you hit some metal, you only need to replace one cutter instead of the entire blade. Also, because they have four sides, you can just turn them 90 degrees when they get dull. This allows them to last much longer than classic straight knives.

Helical Heads are also better at dealing with difficult grain and generally give better results.

The fact that the standard model has standard knives and not quick-change ones makes the upgrade to helical head cutters even more of an upgrade. It is more expensive, however, at about $500. In percentage terms this is about the same upgrade cost as for the 6-inch jointers.

Even though it is more expensive, the upgrade is so significant that we would strongly recommend it. Because of all the time and energy saved from setting up the blades it will be worth it in the long run. Add to that the lower costs and all the advantages and it seems like a no-brainer to get the helical head model unless your budget is really tight.

Knowing the difference between the four models, you may wonder whether you should get the 6 or 8-inch jointer. Which one is right for you depends on multiple things, but in most cases we think the 8-inch jointer is the way to go.

Size is the key word here. Unless you’re always working on small items like boxes, 6 inches is going to be fairly limited. When you want to make a table top or any large surface you will probably be handling boards wider than 6 inches.

This is a major downside to the 6-inch models, because you will have to rip the boards down to less than 6 inches, and then glue them back together. If you have many boards to process, the work really piles up.

It is not a question of compactness, because in terms of width, an 8 or even 10-inch jointer would not be much larger than a 6-inch one. The 8-inch jointer is longer though, so if it doesn’t fit in your shop, the 6-inch model is your only choice.

One thing that may help to work with the limited width of these jointers is to let your lumber supplier already rip boards to a size that fits on your machine. This will save you time and energy having to resize wider boards.

TIP: If you want to find a good deal for any of these jointers, keep an eye on our price tracker. We track machine prices for multiple different stores and update them on our site daily.

We hope you find this guide helpful! Of course, we’re also curious to hear your opinion on JET’s jointers. Which model would you go with? Let us know in the comments below.

© Machine Atlas 2025

There are no comments yet, be the first to leave one!

Every comment on MachineAtlas is read and answered. And if you know some useful info or tips, please share them. You could really help out some fellow woodworkers!