Powermatic makes 10 different jointers. Which one is right for you? Find out their differences in this article.

Powermatic offers 10 different jointers that, at first glance, all look quite similar. How do you know which one you is right for you? In this article we’ll show you the differences between all their models, discussing their pros and cons, to help you find the right jointer for your specific situation.

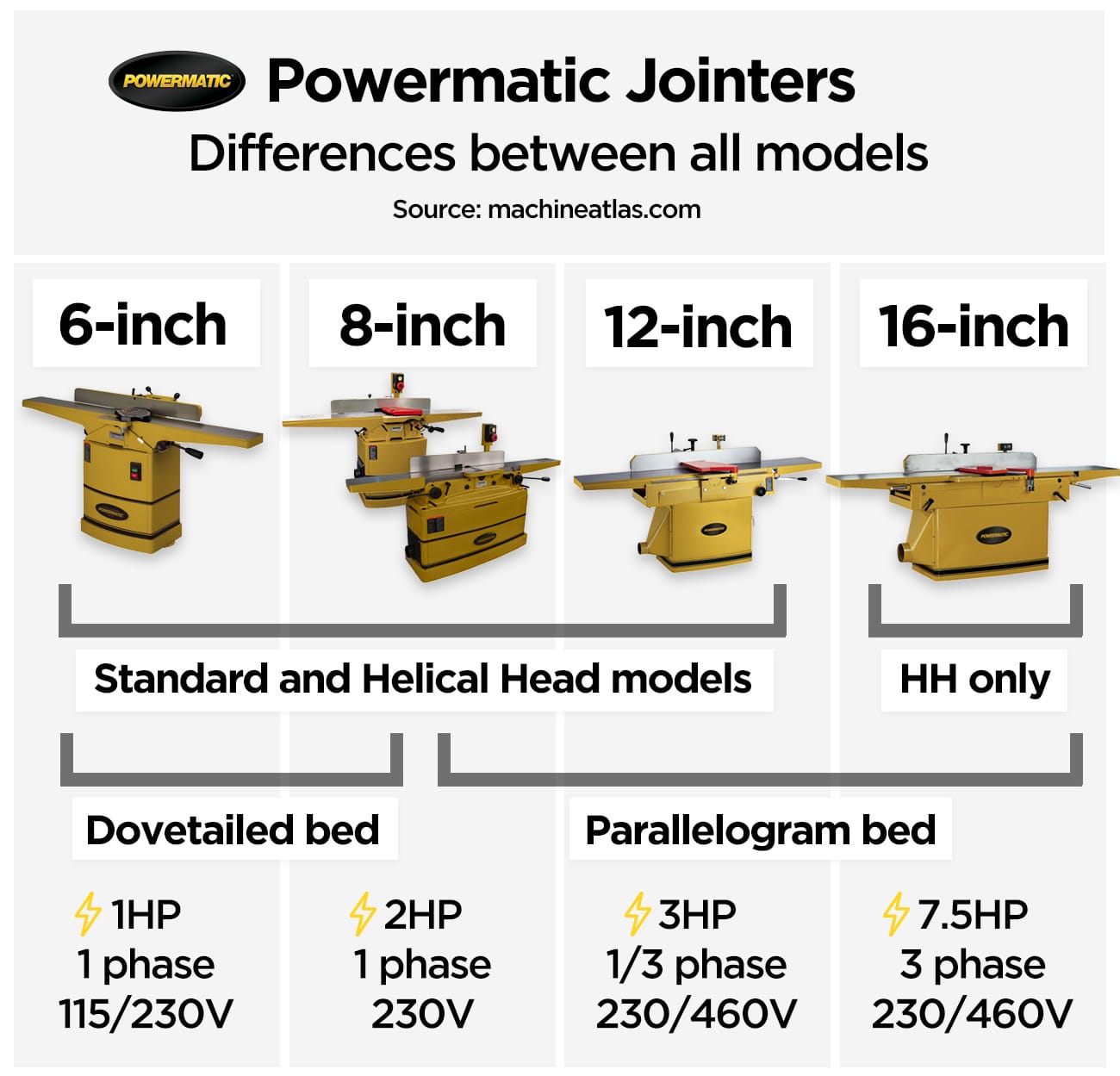

The infographic above may help you make sense of the different types and models of jointers Powermatic makes. For each size category you can see how they are wired, so you can see if they work in your shop.

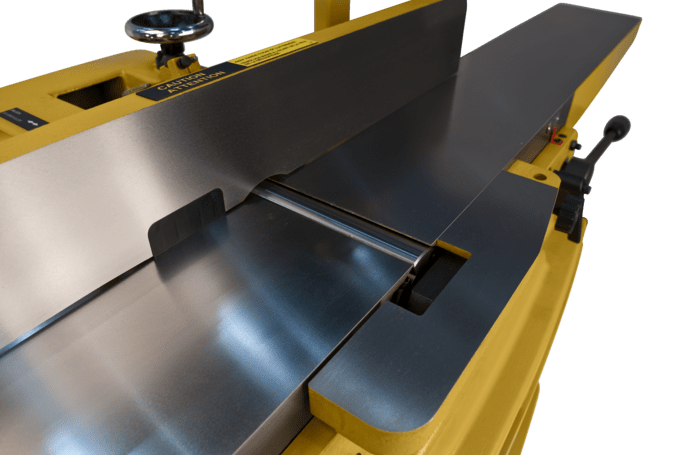

What all models share is that they have relatively long tables, made of cast iron. They all also have an American-style pork chop guard, which moves out of the way as you push the workpiece over the blades.

The smaller models use a classic wedge-bed design, while the larger ones are parallelogram jointers, which we’ll discuss in more detail in the next section. They all have slightly different fences, with those on the smaller models being more finely adjusted, and those on the large models being more sturdy.

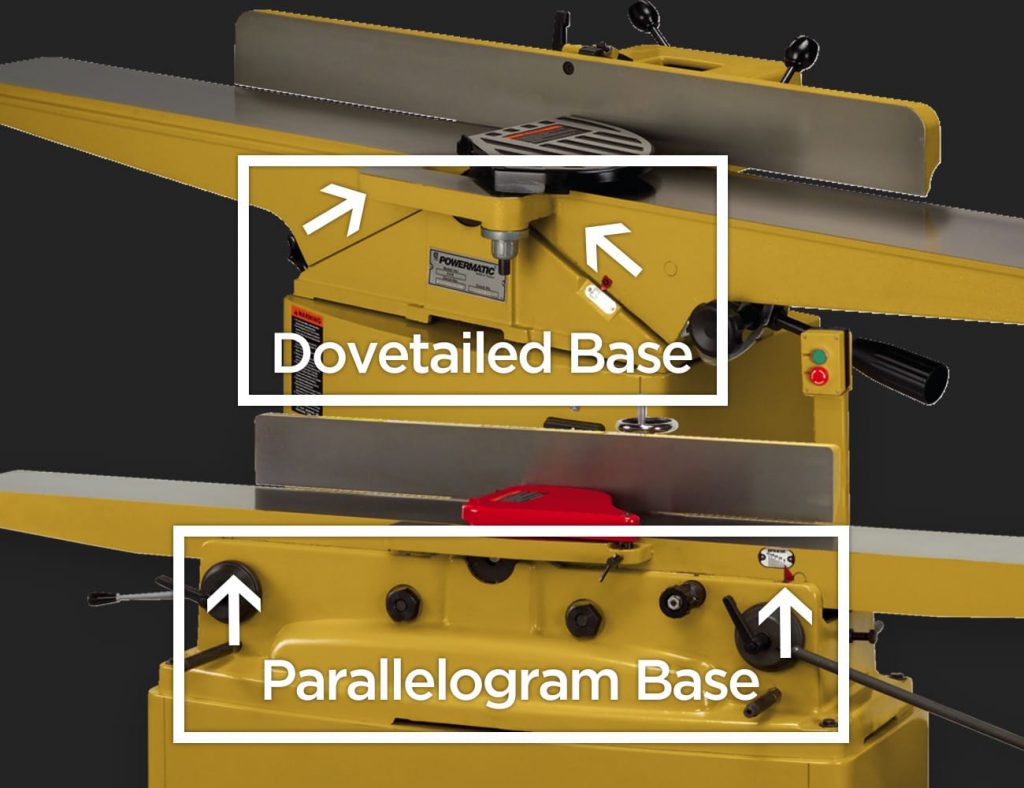

As shown in the infographic, the 6-inch and cheaper 8-inch models use a dovetailed wedge-bed base, while all the bigger and more expensive have parallelogram beds. What is the difference? And how much does it really matter?

Wedge-bed jointers move up and down over dovetailed ways. When you raise or lower the infeed and outfeed table the bed slides over a diagonal piece of (usually) cast iron. The dovetail shape is there to eliminate side play.

Since you are moving cast iron over cast iron, there is some friction between the table and the base every time you move the tables up or down. If you do this very often, there is a chance the friction will wear out the metal, and the tables can start to sag. This in turn can make the tables go out of parallel, which makes straight jointing difficult.

The parallelogram design doesn’t have this problem, because it is moved up and down in a different way that doesn’t involve cast iron moving over cast iron. Rather it is secured on two sides that pivot following a parellelogram shape, as seen below.

Check out this video by Matthias Wandel if you want to understand the parallelogram jointer design in more detail.

The parallelogram design has two distinct advantages: It is easier to move it up and down, since there is no friction of metal sliding over metal, and it is much less prone to wear. Depending on the implementation, it can sometimes also be easier to adjust a parallelogram jointer.

However, most people don’t actually change the height of their jointer all that often. And if they do they will only change the setting a minimal amount. This means the sagging problem of dovetail wedge-bed jointers is unlikely to become a problem for most people. It also makes the easier height adjustment of parallelogram jointers much less important.

There may be other reasons for picking jointers with parallelogram bases (they tend to be longer and heavier). However purely based on the design itself, there is no significant reason to pick one machine over the other.

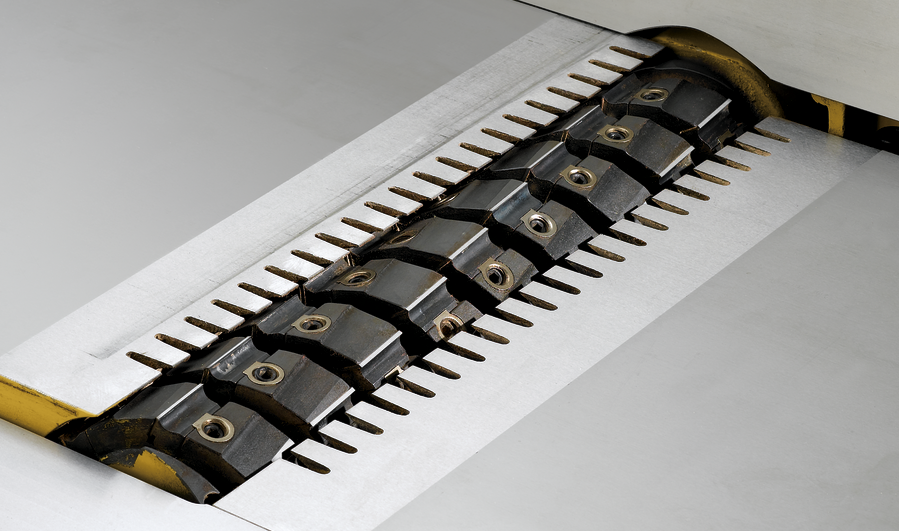

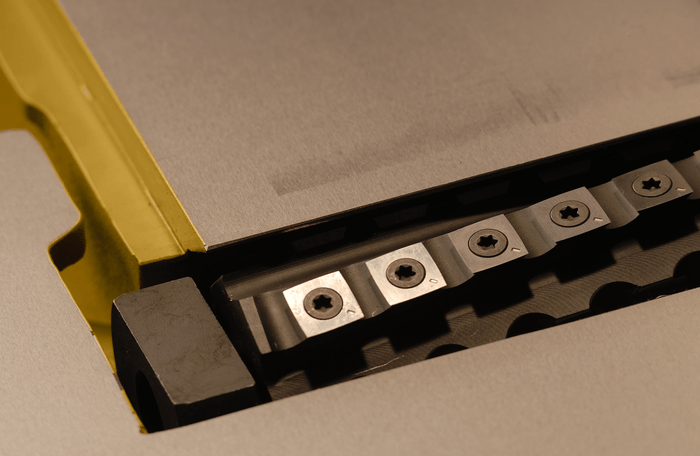

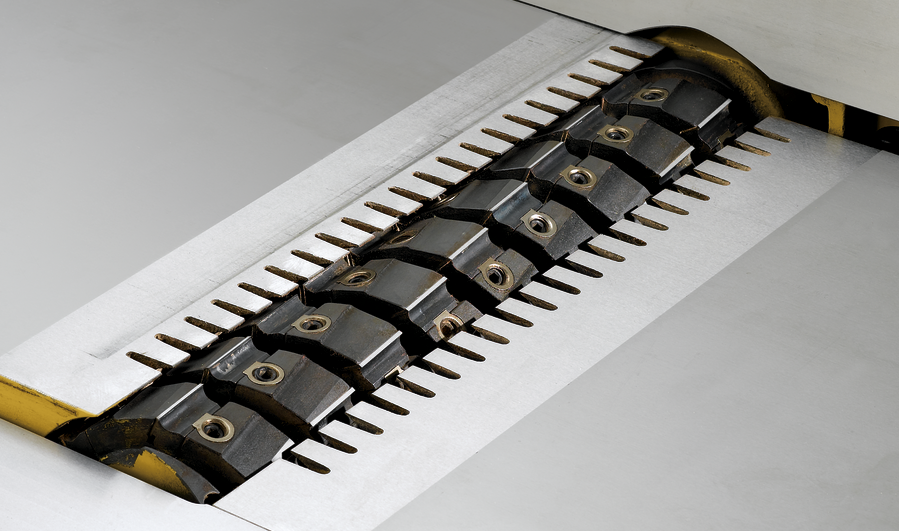

Another important decision when picking one of the Powermatic jointers is whether to go for a Helical Head cutterhead or standard blades. Every Powermatic jointer is available in both a helical head and a standard model, except for the 16-inch one which only comes with helical head cutters. The question is: Which type of cutterhead is best?

If you are deciding purely based on quality and functionality, the decision is simple: Helical head cutters are better in nearly every way. They are better at dealing with difficult grains, are quieter (up to 20dB), last longer due to their four sharp sides, and are much easier to set up. Also, if you hit a nail in the wood, you only have to replace one cutter insert instead of a whole blade.

The only small downside on Powermatic’s smaller machines is that you cannot do any rabbeting with the helical head cutters. This is possible on the 12-inch and 16-inch models however.

Straight blades have many downsides compared to helical head cutters. The main problem is the long time spent and the (possible) frustration that setting the blades up gives. And if you get your knives sharpened, you get to do the whole fun process all over again.

However, on the 6 -inch dovetail wedge-bed models (the 54A), Powermatic actually offers Quick-Set straight blades. Once set up once, you can very quickly replace them and set them to the correct height again.

These blades still lack some of the benefits (noise, cut quality) of helical head cutters, but they at least get rid of the frustrating experience of setting up standard straight blades. Why Powermatic has not added these blades to the bigger machines is a mystery to us. Perhaps most people already pick helical head cutters anyway.

One of the most important considerations when looking at the different Powermatic jointers is what jointing width you want. Prices go up steeply as you increase your desired jointing width.

The reason for this is that for a bigger machine you don’t just need some additional cast iron for the tables, but you’ll also need a heavier base, longer cutterhead and a stronger motor. This is needed because there is simply more wood to cut on each pass.

If you mostly use the jointer to create a first straight edge to then cut the boards on the table saw, a smaller 6-inch jointer could be sufficient. The same goes if you only make smaller objects.

However, if you want to do face jointing, you’ll quickly find that 8-inch jointers are really the minimum size. And even then 8-inches can be on the small size, but it’s manageable if you make sure to pick rough lumber that fits these dimensions.

One solution for dealing with wider boards is to rip them in two on the table saw, joint them separately, and then glue them back together again.

If that sounds like too much work (and it is if you want to run a production shop), you might want to consider a 12-inch jointer. These will handle 90% of the use cases for the average user.

Powermatic also offers the PJ1696, a 16-inch jointer, which is really only needed for production shops that want to joint really large boards. Not many amateur woodworkers will ever need a machine this size.

How much power you need depends on three main factors: The jointer’s width, the depth of cut, and the hardness of the wood. A smaller jointer needs less power than a big one, and if you take off less material in one pass you also don’t need as much power to push the blade through.

Powermatic’s jointers tend to have enough power relative to their size, but the bigger ones are increasingly powerful. If you tend to handle mostly very hard woods, you might want to jump to at least the 8-inch models to be sure you have sufficient power.

Powermatic makes two 6-inch jointers: one with quick-set straight blades, and one with helical head cutters. The helical head upgrade costs about 25-30% extra.

They are practically identical machines, except for the cutterheads. The only other way they differ is the fact that the rabbetting ledge (though present on both machines) can only be used with straight blades, not with helical head cutters.

TIP: In this video, George Vondriska of the Woodworking Guild of America shows how to use the rabbetting ledge on the Powermatic 54A.

Due to their limited size and power, these machines are aimed at hobbyists. This is further supported by the fact that it is the only Powermatic jointer that comes wired at 115V (it can be rewired to 230V). This means nearly everyone can use it and you can just plug it in and start jointing straight away.

However, the 6-inch jointers do still have great build quality and longer tables than most comparable models by competitors. This means they could be a viable option for professionals who only process small workpieces, but most people would upgrade at least to the 8-inch models.

TIP: This video shows how to align the infeed and outfeed table with a dial indicator on the Powermatic 54A.

Purely based on their capabilities, the Helical Head model (the 54HH) is the best 6-inch jointer. It is quieter, easier to use, deals with difficult grains better, and cheaper to replace blades in the long run.

However, the 54HH cannot be used for rabbetting, and it costs 25 to 30% more than the 54A. So, if you are willing to pay for the premium, and rabbetting is not an essential function for you, then the 54HH is the way to go.

If you prefer to save a bit of money, or if rabbetting is a key functionality for you, then the 54A would be the best pick.

| Store | Price | |

|---|---|---|

| $1899.99 |

| Store | Price | |

|---|---|---|

| Price Hidden |

In contrast to the 6 and 12-inch jointers, there are actually two different designs for Powermatic’s 8-inch jointers — one with a dovetail wedge-bed base, and one using a parallelogram design.

Besides the design of the base of the machines, there are a few other differences between the two types of jointers. The parallelogram jointers have longer tables (254mm extra), and are almost 100kg heavier due to the longer base. This comes at a price premium of about 20-25% (about $500).

For each design there is both a model with standard blades, and a model with helical head cutters. These models are identical except for the cutterhead, and for the fact that rabbetting cuts are only possible on the standard blade models.

Though still slightly on the small side for face jointing, 8-inch jointers are capable machines fit for both hobbyists and professionals. Both the parallelogram and the dovetail models are wired at single phase 230V, so they cannot be used in a standard 115V wired shop.

Home users probably use their jointers less and therefore also change the height of their tables much less often than professionals. That’s why we think the dovetail model, coupled with it’s 20-25% lower price, is more aimed at hobbyists.

On the other hand, the parallelogram model is aimed more at professionals, because it will last longer under heavy use, it has longer tables, and is more expensive. However, both models are quite close in quality and performance, and would make a fine addition to both a small professional workshop and a hobbyists shop.

Of the two models, the parallelogram (the PJ882) jointers are slightly better than the dovetailed ones. Their design is easier to use, lasts longer, and they also have longer tables and a heavier, longer, more stable base.

Within each design, the helical head models (the PJ882HH, and the 60HH) are objectively better than the standard blade models. As mentioned earlier, helical head cutters have many advantages over standard ones. Add to that the fact that Powermatic’s 8-inch jointers lack the quick-set blades of the 6-inch jointers, and the helical head upgrade becomes even more attractive.

The only minor downside to the helical head jointers is that they cannot be used for rabbetting. This is not a feature many people use, but if it is essential to you, you’ll have to settle for one of the standard blade models.

Powermatic’s 12-inch jointers are large, heavy, professional machines. Their size and power makes them excellent at face jointing. Their base uses the same parallelogram design as the 8-inch jointers.

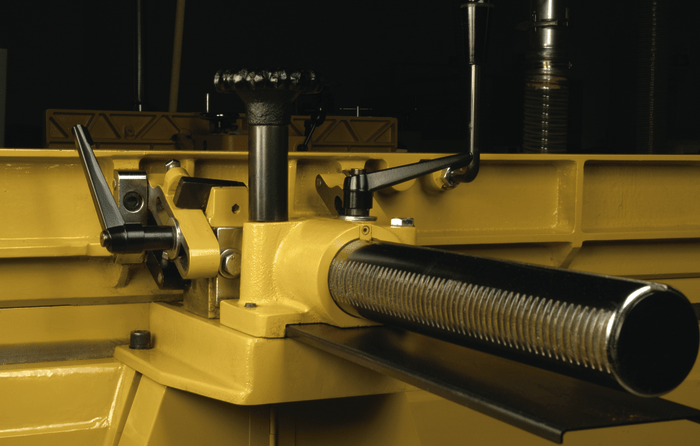

One difference with all the smaller models is that that the fence uses a different design. It is mounted on a sturdy horizontal metal bar that can be moved forward and backwards with a rack and pinion system. The advantage of this is that the fence is secured much better.

This helps when jointing large, heavy boards, which might bend less sturdy fences, resulting in warped boards. However, the disadvantage is that the fence cannot be moved to a specific angle accurately with a handwheel. There are some positive stops available though, so once you set it up at the right angle, it shouldn’t be as finicky.

Powermatic’s 12-inch jointers are quite simply machines for professionals. They are large, sturdy, powerful, and are wired to run in professional shops. There is both a single phase (230V) model, and a three phase one, which can be wired at both 230V and 460V.

Just as with all the smaller Powermatic jointers, there is both a standard (the Powermatic 1285) and a helical head (the Powermatic 1285 Helical Head) model available.

The Helical Head model is objectively better, as already outlined earlier in this article. The advantages of helical head cutters are probably even more helpful in a professional shop. Professional woodworkers are more likely to use higher quality woods, with difficult grains, which get much better results with helical head cutters.

Professional woodworkers also wear out their blades much faster, meaning they need to resharpen and reset their blades much more often than hobbyists. Add to this the additional cost of sharpening and blade replacements, and helical head cutters also become more interesting financially in the long term.

All in all, we see no reason why a professional woodworking shop would go for the standard blades model. The helical head cutters will pay for themselves in the long term, both due to their replacement costs, longer age, and reduced frustration and time spent on blade replacements.

Type of machine

Jointer

Designed in

United States

Manufacturer

Powermatic

Prices from

Finally, Powermatic also offers a 16-inch jointer. It is pretty much identical to the 12-inch models, except of course being bigger. To make things even simpler, it is only available in one flavor — with a helical cutterhead.

Like the 12-inch jointers, it is a professional machine with a powerful 7.5HP motor. It runs on three phase only, and can be wired for both 230 and 460V. Add to that the weight of almost 600kgs and you’ll quickly get a sense of the bulkiness of the machine.

Not even all professional shops need a machine this size, and it is probably most useful for people who face joint big slabs from large, old trees. Many people use a wide belt sander or drum sander for this purpose as well.

Powermatic offers a wide range of jointers, from small 6-inch hobbyist ones, to massive 16-inch industrial machines. Depending on your specific needs, there’s a good chance that they offer a model that is right for you.

If you are a hobbyist on a limited budget, we would recommend either one of the 6-inch models, or the standard 8-inch dovetailed jointer. These will do most basic task without breaking the bank.

If you are a hobbyist with a bit more to spend, the dovetailed 8-inch jointer with helical head cutters would be the perfect choice. Its size is enough for most hobbyist tasks. If you really want the best machine for your use case, you can consider upgrading to the parallelogram jointer.

For professionals in smaller workshops, the 8-inch parallelogram jointer is an excellent choice. Its long tables, long and heavy base, and parallelogram design make it a very durable machine that will handle almost anything you throw at it.

Professionals who find 8-inch jointers too limited in size can look at Powermatic’s 12-inch 1285 series. Although more expensive, they offer much more capacity and a sturdier fence. We feel the helical head cutters are a must-have upgrade in this price range.

If 12-inch jointers aren’t large enough for you, then you might get lucky with Powermatic’s 16-inch jointer.

Hopefully you found our guide helpful. If you have any feedback, experiences, or anything else you would like to know or share about these machines, let us know in the comments below!

© Machine Atlas 2025

There are no comments yet, be the first to leave one!

Every comment on MachineAtlas is read and answered. And if you know some useful info or tips, please share them. You could really help out some fellow woodworkers!